Whether it’s powering a forklift, a boat or an 18-wheeler, diesel engines are vital to ongoing performance. Regular maintenance can keep it running well for years to come, regardless if it is a new diesel engine or an old one that needs a little more TLC.

Being responsible in the care of your diesel engine can save you both time and money. In this guide, we’ll offer some maintenance tips for diesel engines, as well as a diesel engine maintenance checklist that you can use throughout the year as you keep up with the needs of your engine.

Why Diesel Engine Maintenance Matters

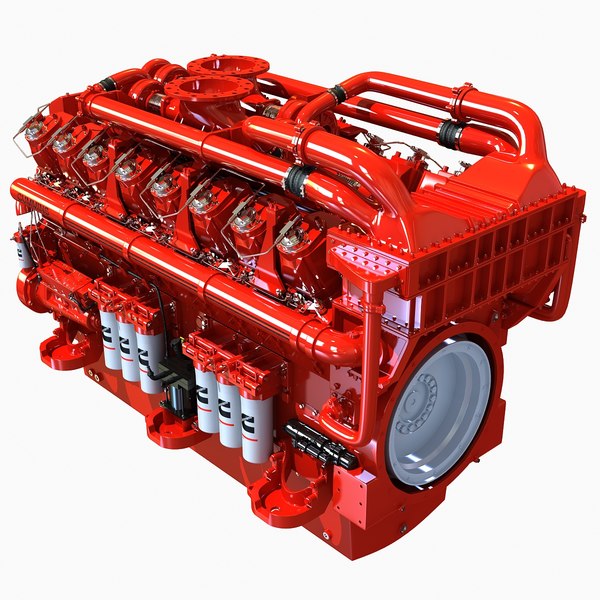

Maintenance of a diesel engine can be more of an involved process than the maintenance of a gasoline engine. These heavy-grade parts typically see much more use than their counterparts and have more requirements to keep them running smoothly.

Taking care of a diesel engine is an important investment. By keeping parts in good shape, you save yourself the time associated with breakdowns and repairs and get to avoid the cost of expensive parts. Repairs on a diesel engine can be more difficult than those on your standard car.

You’ll need to give your engine special attention if you frequently expose it to rough environments, like extreme or varying temperatures, saltwater and particles such as dust or sand.

Responsible ownership of your diesel engine includes regularly cleaning and servicing it, as well as keeping parts updated and replacing them as needed. If you drive in a cold region, winterizing your engine will also be necessary.

Another benefit of treating your diesel engine right includes the ease of use that comes with it. You should see easier use in a truck that’s running on a clean, de-sludged engine, including a lack of hard startups. You may also see increased fuel economy, as your engine becomes more efficient and uses its fuel in better ways.

Daily Maintenance Schedule

A daily inspection ensures that your engine continues to run smoothly. It prevents any unwanted surprises and helps you to watch and prepare for any building issues.

The first step is to check the overall condition. A simple visual inspection can enlighten you to any obvious issues such as leaks, corrosion, and cracks.

Check the exhaust for any leaks or excess heat coming out.

Check the fuel system for any cracks or abrasions.

If you find a leak, locate the source, which could be in multiple different components. An oil leak in an engine could be coming from degrading gaskets and oil pan leaks, among other areas such as seals and valves.

Check your levels daily as well, to avoid being unprepared, and to keep a close eye on any changes that could indicate a problem. In addition to making sure your supply is sufficient, check that they are in good condition without contaminants or discoloration. Some materials to keep an eye on include:

Coolant

Fuel

Oil

If you use intercoolers or coolant heaters, you’ll also want to check their condition as well. Ensure that there are no cracks or rips.

Weekly Maintenance Schedule

Some aspects of an engine should be maintained on a weekly basis. This includes tasks like draining and cleaning.

1. Clean the air filter. Some of the symptoms of a bad or dirty air filter include lower fuel economy, hard starts, vibration, black smoke from the exhaust and abnormal engine sounds. With normal conditions, an air filter should be replaced every 30,000 miles or so. Many drivers lump this task in with their oil change, but cleaning your filter may keep it flowing easier. You may be able to vacuum the filter or swish it around in water to clean it, giving it plenty of time to air dry.

2. Drain water from the fuel tank. With a water separator, the water that doesn’t mix well with fuel drops to the bottom of the tank. In a diesel engine equipped with this, you’ll need to drain the water out regularly to avoid contaminated fuel. Be sure to catch the fuel in a container to watch what you’re draining.

Monthly Maintenance Schedule

After about a month, you’ll have some parts that need a more in-depth inspection.

1. Check your battery charger. Test the battery voltage and electrolyte levels. One way to check the battery is to watch the headlights. If you rev the engine and the lights get brighter, your alternator may not be producing the right current for your battery.

2. Check the coolant concentration. Antifreeze keeps your radiator working to cool your engine efficiently. Make sure that your radiator is full and that the coolant looks appropriate. It is typically colored red, green, blue or yellow without any rust or debris floating around. It shouldn’t have sludge or oil on the surface either. Make sure the engine is completely cooled before you open the radiator. If it is still warm, you may have dangerously hot coolant splashing around, or you could damage the engine block.

3. Check the drive belt tension. The drive, or serpentine belt, connects several components and helps deliver power to them. To keep things running smoothly, it is crucial that this belt is taut and in good condition. A belt starts to slip when the load on a generator is too heavy. Whenever it stretches to adjust for this, the belt is slackened, which makes it lose some efficiency. Some warning signs of a bad belt include an engine that overheats or a flat battery. To check the belt, make sure it is taut and doesn’t have any cracks. If you remove the belt and bend it slightly, you can see any cracks appear much more easily. You’ll also want to take a look at the pulleys for cracks, damage or bumps.

To really see how tight your drive belt is, you may need to do some measuring. Find the exact midpoint of the belt’s longest section and hold it between your finger and thumb. As you move it from side to side, pay attention to how much it moves. It should have around half an inch of slack. Any more is too much and any less is too little. This is a general guideline, and you may want to check your owner’s manual for a more exact measurement on your belt’s specifications.

6-Month Maintenance Schedule

At the six-month mark, you’ll have more intensive checks to do.

1. Clean the crankcase breather. The crankcase breather releases any gases that become trapped in the engine compartment, reducing the pressure in the engine. This piece reroutes the gases into the carburetor. When the crankcase becomes clogged, it can block airflow, reducing its effectiveness and possibly leading to blown seals or gaskets. Excessive exhaust is another symptom of a clogged crankcase breather.

2. Check radiator hoses. Radiator hoses keep your engine running at the ideal temperature by moving coolant throughout the system. Like every part, hoses can wear down over time, so you’ll need to make sure that they are in good condition. While the engine is still warm — not hot — give the hoses a squeeze. They should be firm. If they are hard, soft or squishy at any point, they need to be replaced. Also check the connectors, ensuring that they are not corroding or damaged.

3. Change oil and filter. This one is pretty straightforward. Many say you should get an oil change every 7,500 miles or annually, as a minimum. This schedule keeps your oil from building up any contaminants that will make your engine less efficient.

4. Change coolant filter. A coolant filter can both filter the coolant and supply it with nitrite, which provides more protection. However, nitrite levels of over 800 ppm can be damaging to the system, so you’ll need to monitor these levels. Professionals may check this, but you can also buy test strips at auto parts stores or truck repair shops. If you’re using a coolant filter, change it out every six months or so.

5. Change air cleaner elements. Cleaning the air filter is another necessary maintenance component. Some engines have two filters — a primary and secondary one. With the engine off, you’ll need to change your filters according to the manufacturer’s instructions. Depending on the methods required and if air bleeding is necessary, it may be cheaper to get this done by a professional.

Annual Maintenance Schedule

As you approach a full year of running your engine, you’ll have yet a few more maintenance procedures to perform, along with all of the other regular tasks you perform.

Start by inspecting the transmission cooler. Make sure your hoses are tight and in good condition, with no leaks or cracks present. You may have a bad transmission cooler if your fluid level drops quickly, leaks or burns. Watch out for an engine that overheats or makes abnormal noises.

You’ll also want to take a look at the fuel cooler. A fuel cooler, common on marine applications, can help the atomization process in an engine, but contamination can cause damage to the whole system. A professional should typically do this cleaning.

If winterizing your engine, yearly maintenance may be a good time to perform those tasks.

Prep the fuel with liquid treatments: Deicers and cold-flow improvers are common additions to fuel in preparation for the coldest months.

Check filters: Though you’ll still want to do this regularly, fresh filters can help reduce the chances of frozen water in the fuel tanks and lines. Keeping the tanks full and the water separator filters in good condition helps too.

Prep the battery: Make sure it is in good condition, with tight connections. The battery goes through much tougher conditions in the winter, so helping it be as prepared as possible may save you from a dead battery in the dead of winter. If your battery is toward the end of its lifecycle, you may want to replace it before cold temperatures hit.

Inspect the cooling system: This system again sees extensive stress in the wintertime. Make sure your parts and coolant levels are good and that you’ve added in any treatments.

Look over parts: Check all belts and hoses for physical condition. As you would look for in more frequent checks, keep an eye out for any cracks, bulges, loose hoses, wear and tear or leaks. Any of these can cause quick deterioration with the added stress of extreme and fluctuating temperatures.

How to Tell If Your Engine Requires Immediate Assistance

Even with frequent and proper maintenance, your engine may still need an immediate fix. In these instances, problems can lead to detrimental issues to your entire system or become dangerous. Some signs that you need to immediately address in an engine include:

Hard starts: An engine that struggles to start up or clatters on idle can signal a wide variety of issues. They may come from leaks in the fuel lines, clogged filters or contaminated fuel. If hard starts occur, look into them, and consult an expert if you can’t find the source.

Colored exhaust: Exhaust that is black, white or blue can also indicate a range of problems. These colors may signal leaking oil, bad injectors, temperature problems or clogged filters, among other things.

Fuel-injection problems: The injection system is a major component of an efficient engine, and if this part isn’t functioning well, you need to have it checked out. The fuel injection system typically requires servicing between 100,000 and 120,000 miles. Fuel leaks can occur for a variety of reasons associated with normal use.

Excess smoke: Of course, if your exhaust starts spewing clouds of completely black smoke, there is a major problem somewhere that could lead to some costly damage to an engine.

A lack of acceleration power: If your fuel filters are worn out or clogged or you have a dirty catalytic converter, you may see problems with acceleration. Transmission and engine temperature problems can also be significant culprits.